Precision is critical in the complex world of modern manufacturing. Computer Numerical Control (CNC) machining has emerged as a leading technology, offering a wide range of techniques customized to meet the unique requirements of different applications, as industries demand ever more complex and accurate components.

Modern manufacturing processes now revolve around CNC machining, which is powered by automated control and digital precision. With applications ranging across industries as diverse as aerospace, automotive, electronics, and healthcare, each cnc machining types represents a distinct method of transforming raw materials into intricate components.

What Is Machining With A CNC Machine?

Computer Numerical Control (CNC) machining is a precision manufacturing technique that uses computer systems to regulate the motion of tools and equipment. In order to precisely shape and cut materials like metals, polymers, and composites, it entails translating digital 3D models into machine-readable code. It makes it possible to precisely and automatically fabricate parts using digital 3D models. CNC machining is a mainstay in many industries for creating complex and customized components because of its automated process, which guarantees high accuracy, repeatability, and efficiency.

The Most Common Forms of CNC Machining

CNC machining is the umbrella term for a number of procedures that automate machine tools for precision manufacturing using computer numerical control (CNC) systems. The following are the main kinds of CNC machining:

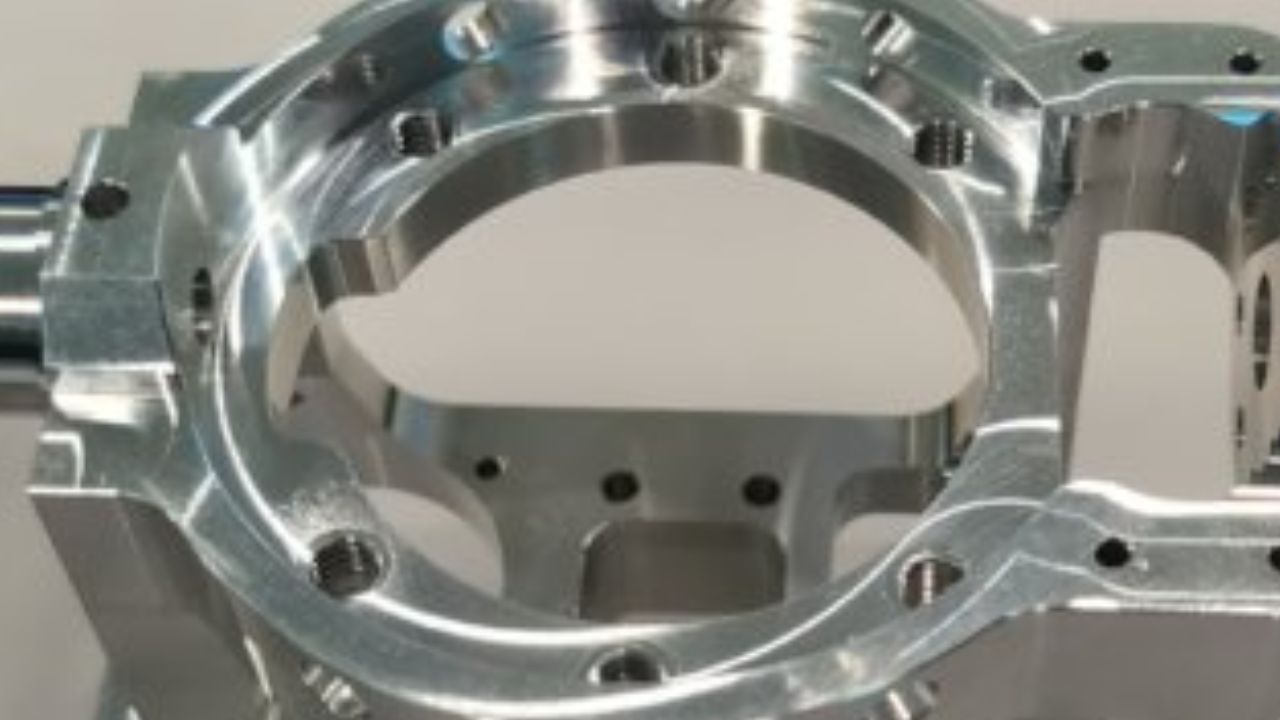

Milling Machines

One of the most used CNC machining techniques is milling. In order to create the desired shape or form, material is removed from a workpiece using rotary cutters. Drilling, tapping, face milling, and contour milling are just a few of the tasks that CNC milling machines can handle. Because of its adaptability, milling is used extensively in the aerospace, automotive, and medical manufacturing industries to produce components with complex geometries.

Turning Machines

Lathing, or turning, is another essential CNC machining operation. Turning is the process of rotating a workpiece while a cutting tool removes material to form cylindrical shapes, like rings, shafts, and rods. CNC turning machines are essential to the production of parts because they are widely used to produce components with rotational symmetry.

Drilling Machines

The purpose of CNC drilling machines is to drill holes in workpieces. These devices achieve accurate whole placement and material removal with multi-point drill bits. When producing printed circuit boards, aerospace structures, and engine components—components where precise whole patterns are crucial CNC drilling is a necessary tool.

Electrical Discharge Machining (EDM)

EDM is a special kind of CNC machining where the material is removed from a workpiece by means of electrical discharges. EDM comes in two main varieties: wire EDM and sinker EDM. Whereas Sinker EDM uses a shaped electrode to create the desired form, Wire EDM uses a thin, electrically charged wire to cut through the workpiece. EDM is especially helpful in the machining of hardened materials that are difficult to machine with conventional techniques, as well as small and delicate parts.

Plasma Cutting Machines

Electrically conductive materials are cut by CNC plasma cutting machines using an ionized gas jet at high velocity. These devices are frequently employed in the production of metal components because they provide rapid and accurate cutting. Particularly in the construction, automotive, and metal fabrication industries, CNC plasma cutting is very common.

Waterjet Cutting Machines

A high-pressure water stream combined with abrasive particles is used in waterjet cutting, a flexible CNC machining technique, to cut through a range of materials. Because of its reputation for cutting materials without producing heat, this method is appropriate for materials like composites and plastics that are sensitive to high temperatures. Architectural design and aerospace are two fields that heavily rely on waterjet cutting.

Conclusion

The complex needs of contemporary manufacturing are met by a variety of diverse and dynamic processes found in the world of CNC machining. Each CNC process has its own benefits and uses, ranging from drilling and turning to electrical discharge machining, plasma cutting, waterjet cutting, and milling and turning.